Recycling

Benefits from service

We appreciate your trust. Our clients choose us and our products because they know we're the best.

Sustainable

Efficient

Advanced

Trustworthy

Compliant

Assured

Types of Distillation

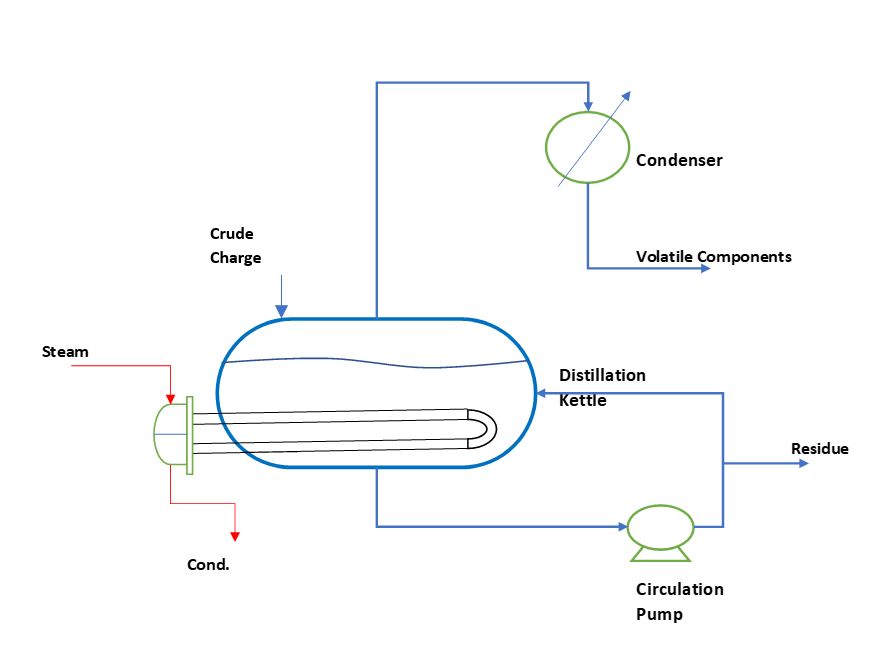

ATMOSPHERIC DISTILLATION

FRACTIONAL DISTILLATION

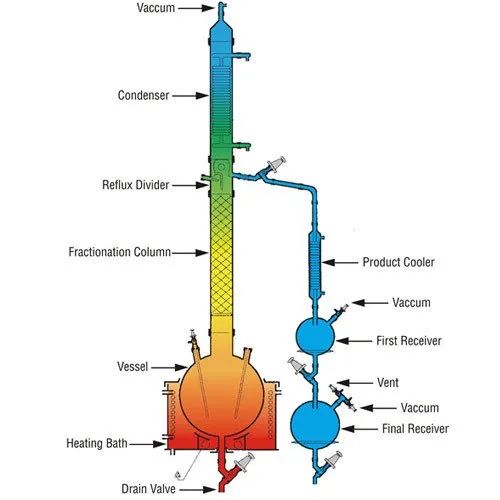

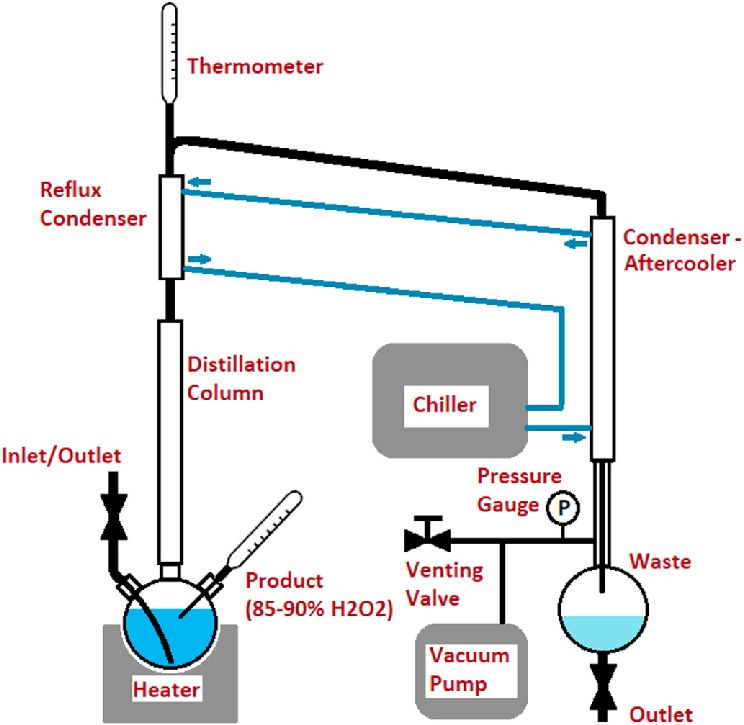

VACUUM DISTILLATION

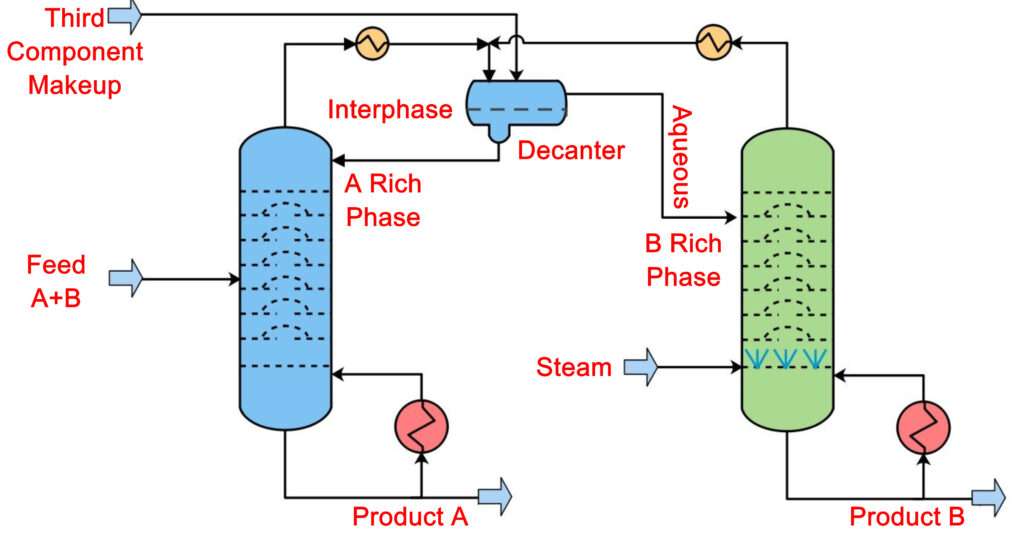

AZEOTROPIC DISTILLATION

Leading The Way In Valorization and the Recovery of Industrial Waste

Regd Office:

Unit:

Office No 4, Bld No 11, Pushpanjali CHS,Tilak Nagar, Chembur, Mumbai - 400 089INDIATel: +91 22 2529 1272 / 73Fax: +91 22 2529 1271Click here for directions

A/84/1, A/89, Kurkumbh MIDC, Tal Daund,Dist Pune, Maharashtra - 413 802Tel: 02117 235 297 Click here for directions

Copyright © 2025, Shiv Shakti Oxalate Pvt Ltd All Rights Reserved